Introduction

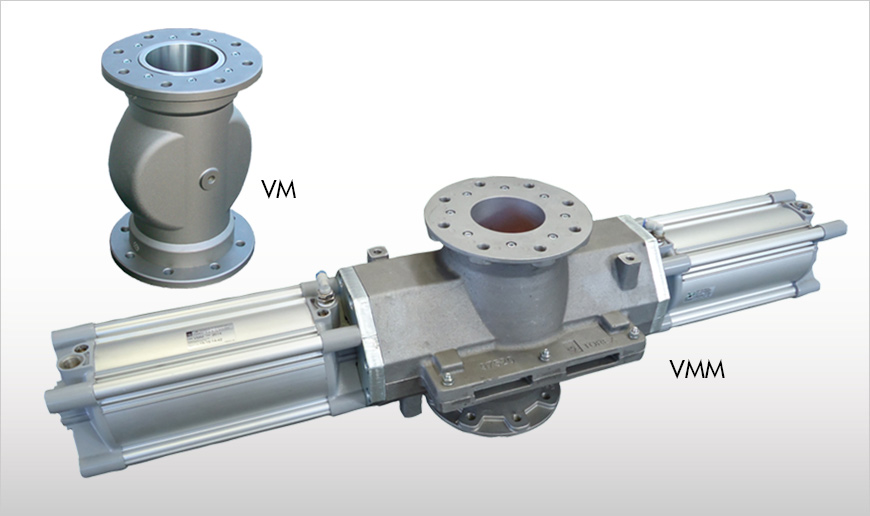

VM/VMM-type Pinch Valves are used for interception of material flow in pneumatic conveying systems, or other pipelines. In addition, they can be installed as a locking device for silo filling pipes.

Easy, quick sleeve and bush replacement

Quick installation and replacement

Particularly low air consumption

Technical Specs

Description

The body of the VM/VMM Pinch Valve is manufactured from aluminium alloy while the sleeves come in fabric-reinforced material. The sleeve support bushes are either made from aluminium alloy, hardened carbon steel, or 304/316 stainless steel.

Function

VM and VMM-type Pinch Valves are used for interception of material flow in pneumatic conveying systems, or other pipelines. In addition, they can be installed as a locking device for silo filling pipes.

Regarding VM only, by introducing compressed air through the threaded bore into the interior of the valve, the internal flexible sleeve is reshaped in such a way as to hermetically seal the passage. With VM Pinch Valves pneumatically conveyed powders, granules, fibres, dense mixtures and liquids can be equally handled.

Regarding VMM only, by introducing compressed air into the two single action air cylinders, the internal flexible sleeve is kept open. In case of no presence of air, the cylinders will reshape the sleeve in such a way that the passage is hermetically sealed. VMM Pinch Valves can equally handle pneumatically conveyed powders, granules, fibres, dense mixtures or liquids.

Features

- Passage diameter from 13 mm (1/2”) to 200 mm (8”) (for VM)

- Passage diameter: 40 mm (1 ½”) – 50 mm (2”) – 65 mm (2 ½”) – 80 mm (3”) – 100 mm (4”) – 125 mm (5”) – 150 mm (6”) – 200 mm (8”) (for VMM)

- Working Temperature: -20 ~ 80 °C (-4 ~ 176 °F)

- Different sleeve materials suitable for material handled

- Different bush materials suitable for material handled

Benefits

- Easy, quick sleeve and bush replacement

- Full bore-through passage without any pressure loss

- No material contact with the body

- Suitable for explosion proof plants (VM only)

- Lightweight in comparison with other makes and other types of valve

- Particularly low air consumption (VM only)

- Food-grade contact parts